Its most well known application is the formation of pvc pipes in the building and construction industry but the benefits of pvc extend far beyond this into the medical electrical and protective clothing sectors.

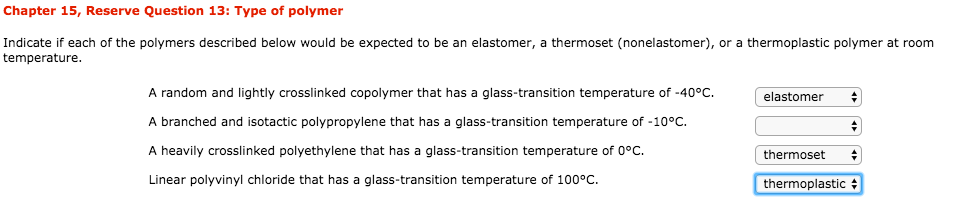

Vinyl chloride polymer thermoplastic or thermost.

Top 10 properties of thermoplastic material.

Polyvinyl chloride pvc is considered a thermoplastic.

By heating the polymer it turns as soft material.

Benefits of thermoset resins.

Because of their high.

Thermoplastics are known for their high molecular weight because intermolecular interactions increase as the plastic is cooled.

The most common thermosetting resin used today is a polyester resin followed by vinyl ester and epoxy.

Polyvinyl chloride commonly referred to as pvc or vinyl is the world s 3 rd most synthesised thermoplastic material.

Poly vinyl chloride pvc ch2 chcl n.

Thermosets and thermoplastics come in a wide range of material options and can serve different applications as long as the limitations of the material are not likely to cause product failure under the intended operating conditions.

Most thermoplastics have a high molecular weight the polymer chains associate by intermolecular forces which weaken rapidly with increased temperature yielding a viscous liquid in this state thermoplastics may be reshaped.

The basic features of these materials remain the same.

It is not uncommon for people working in polymer businesses e g polymer recycling to ignite a small piece of plastic with a cigarette lighter and identify the polymer based on flame test and odor.

Polyurethane pur and pu is a polymer composed of organic units joined by carbamate urethane links.

They can be melted again and again.

Plastic and which are thermoset t.

A thermoplastic is a plastic material that becomes moldable above a specific temperature and solidifies upon cooling.

Polyvinyl chloride pvc teflon.

Polyurethane polymers are traditionally and most commonly formed by reacting a di or triisocyanate with a polyol since polyurethanes contain two types of.

Thermosetting resins are popular because uncured and at room temperature they re in a liquid state which allows for convenient impregnation of reinforcing fibers such as fiberglass carbon fiber or kevlar.

While most polyurethanes are thermosetting polymers that do not melt when heated thermoplastic polyurethanes are also available.

Thermoplastic polymers most of the polymers described above are classified as thermoplastic.

Based on the flame tests identify which polymers are thermoplastic t.

In this article i will be explaining the top 10 properties of thermoplastic materials in a detailed manner.

A thermoplastic or thermoset polymer composition comprises a thermoplastic or thermoset matrix polymer and substantially spherical polymer particles having an average diameter of from 2 to 15 micrometers and a particle size distribution such that at least 90 by weight of the particles fall within 20 of the average particle diameter.

A thermoplastic or thermosoftening plastic is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

High versatility and recyclability.